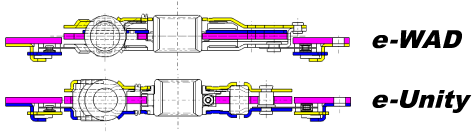

e-WAD, e-Unity

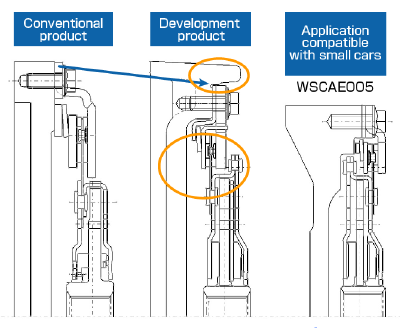

As a measure to achieve carbon neutrality, the HEV, which combines an electric motor with an ICE, plays an important role alongside fully electrified cars to reduce CO2 emissions, especially when the vehicle production process is taken into consideration. We have developed a special damper that focuses on the development issues of HEV systems. By reducing the size of the torque limiter part, we have made it is easier to mount between the engine and motor.

The e-WAD and e-Unity torque limiter dampers are equipped with high-damping performance dampers that improve adaptability to NV issues.

Features

Structure

Achieves weight reduction and cost reduction by reducing the diameter of the skeleton and combining it with the shape of the flywheel

Damper

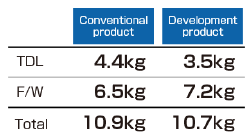

Set e-WAD and e-Unity compatible with in-line 3-cylinder and in-line 4-cylinder engines

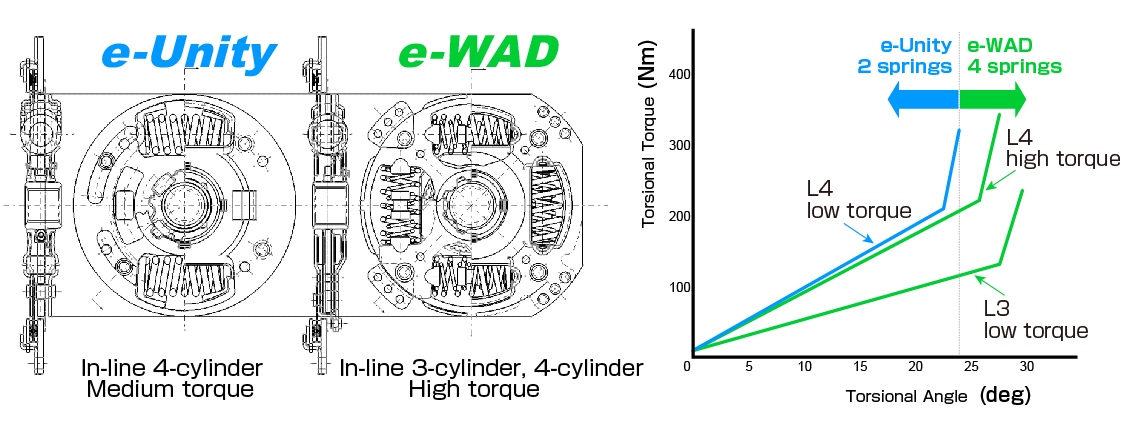

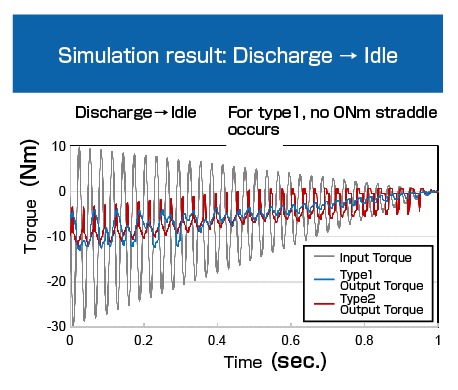

Multi-function AC / DC hysterical mechanism achieves both resonance suppression and fuel efficiency improvement

Limiter

High heat capacity limiter structure realizes reliable power transmission and system protection

Productivity

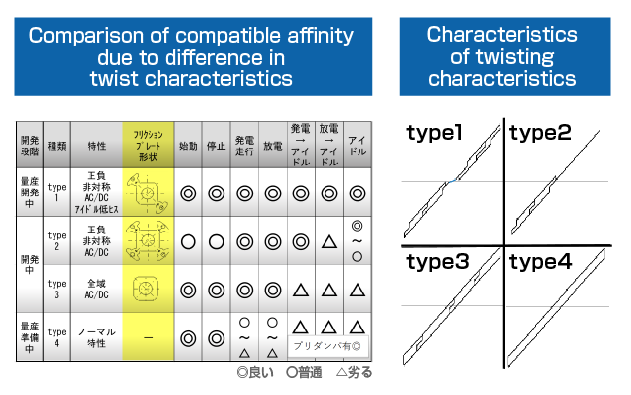

Achieves parent-child taking of multiple parts

Reference exhibition

e-WAD Positive / negative asymmetry AC/DC

e-Unity with integrated flywheel

Structure

Smaller skeleton diameter and redistribution of flywheel inertia

By devising the fastening method of the damper parts, the outer diameter is reduced by overlapping the limiter and the axial direction. The shortage of inertia is covered by the outer diameter and axial dimensions of the flywheel, achieving both weight reduction and cost reduction.

Damper

Two types of wide-angle and low-rigidity damper bodies are available.

Multi-function AC / DC hysteresis mechanism

Achieves 4 types of characteristics with different friction plate shapes (Types 1 to 4)

Improved compatibility of HEV systems (series parallel, series, series with direct connection), resonance suppression and improved fuel efficiency

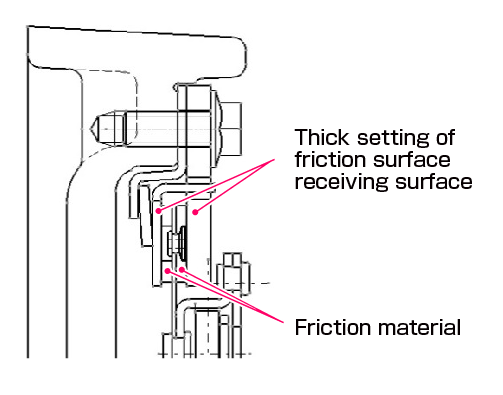

Limiter

Thick friction surface receiving surface, Achieves long life and stable characteristics

Productivity

Improve productivity by parent-child taking of multiple parts and progressive press

(Parent and child parts of the same color in the figure below)